|

| 重組了一台白色的cyclone PCB |

所以新的技術就是要發表新的文章,這一篇主要討論的事 "GRBL 非線性主軸速度PWM輸出解決方案" Open Source的最大好處就是擁有全世界的工程師協助解決問題並提出創新的技術.那真的是件很棒的事情。

什麼是"非線性主軸速度PWM輸出解決方案"因為我們的主軸控制使用PWM輸出,所以輸出曲線是一個線性曲線(0%~100%再依我們主軸最大轉速去換算),我們的主軸並不是這麼的線性,簡單的說我們的主軸馬達轉速有10000轉,而PWM設定50%輸出,照道理講主軸馬達轉速應該輸5000轉,但你實際量測馬達轉速只達到3000,所以為了避免這個問題發生,所以就有人提出了非線性主軸函式。

這非線性主軸函式是 麻省理工學院許可證(MIT)Copyright (c) 2017 Sungeun K. Jeon for 怎麼做呢? 我們需要一個硬體設備。就是轉速計,不管是接觸式和非接觸式的只要能測量出你的主軸真實轉速,就可以做出非線性主軸轉速控制。

而且在這個"非線性主軸速度PWM輸出解決方案"是GRBL v1.1f.20170717 才有的功能所以你不要下載太舊的版本。文件中含有使用說明

+USAGE:

|

+

- First, make sure you are using the stock build of Grbl for the

328p processor. Most

|

+

importantly, the SPINDLE_PWM_MAX_VALUE and SPINDLE_PWM_MIN_VALUE

should be unaltered

|

+

from defaults, otherwise change them back to 255.0 and 1.0

respectively for this test.

|

+

|

+

- Next, program the max and min rpm Grbl settings to '$30=255' and

'$31=1'. This sets

|

+

the internal PWM values equal to 'S' spindle speed for the

standard Grbl build.

|

+

|

+

- Check if your spindle does not turn on at very low voltages by

setting 'S' spindle

|

+

speed to 'S1'. If it does not turn on or turns at a non-useful

rpm, increase 'S' by

|

+

one until it does. Write down this 'S' value for later. You'll

start the rpm data

|

+

collection from this point onward and will need to update the

SPINDLE_PWM_MIN_VALUE

|

+

in cpu_map.h afterwards.

|

+

|

+

- Collect actual spindle speed with a tachometer or similar means

over a range of 'S'

|

+

and PWM values. Start by setting the spindle 'S' speed to the

minimum useful 'S' from

|

+

the last step and measure and record actual spindle rpm. Next,

increase 'S' spindle

|

+

speed over equally sized intervals and repeat the measurement.

Increments of 20 rpm

|

+

should be more than enough, but decrease increment size, if highly

nonlinear. Complete

|

+

the data collection the 'S' spindle speed equal to '$30' max rpm,

or at the max useful

|

+

rpm, and record the actual rpm output. Make sure to collect rpm

data all the way

|

+

throughout useful output rpm. The actual operating range within

this model may be set

|

+

later within Grbl with the '$30' and '$31' settings.

|

+

|

+

- In some cases, spindle PWM output can have discontinuities or

not have a useful rpm

|

+

in certain ranges. For example, a known controller board has the

spindle rpm drop

|

+

completely at voltages above ~4.5V. If you have discontinuities

like this at the low

|

+

or high range of rpm, simply trim them from the data set. Don't

include them. For

|

+

Grbl to compensate, you'll need to alter the SPINDLE_PWM_MIN_VALUE

and/or

|

+

SPINDLE_PWM_MAX_VALUE in cpu_map.h to where your data set ends.

This script will

|

+

indicate if you need to do that in the solution output.

|

+

|

+

- Keep in mind that spindles without control electronics can slow

down drastically when

|

+

cutting and under load. How much it slows down is dependent on a

lot of factors, such

|

+

as feed rate, chip load, cutter diameter, flutes, cutter type,

lubricant/coolant,

|

+

material being cut, etc. Even spindles with controllers can still

slow down if the

|

+

load is higher than the max current the controller can provide.

It's recommended to

|

+

frequently re-check and measure actual spindle speed during a job.

You can always use

|

+

spindle speed overrides to tweak it temporarily to the desired

speed.

|

+

|

+

- Edit this script and enter the measured rpm values and their

corresponding 'S' spindle

|

+

speed values in the data arrays below. Set the number of piecewise

lines you would

|

+

like to use, from one to four lines. For most cases, four lines is

perfectly fine.

|

+

In certain scenarios (laser engraving), this may significantly

degrade performance and

|

+

should be reduced if possible.

|

+

|

+

- Run the Python script. Visually assess the line fit from the

plot. It will not likely

|

+

to what you want on the first go. Dial things in by altering the

line fit junction

|

+

points 'PWM_pointX' in this script to move where the piecewise

line junctions are

|

+

located along the plot x-axis. It may be desired to tweak the

junction points so the

|

+

model solution is more accurate in the region that the spindle

typically running.

|

+

Re-run the script and tweak the junction points until you are

satified with the model.

|

+

|

+

- Record the solution and enter the RPM_POINT and RPM_LINE values

into config.h. Set the

|

+

number of piecewise lines used in this model in config.h. Also set

the '$30' and '$31'

|

+

max and min rpm values to the solution values or in a range

between them in Grbl '$'

|

+

settings. And finally, alter the SPINDLE_PWM_MIN_VALUE in

cpu_map.h, if your spindle

|

+

needs to be above a certain voltage to produce a useful low rpm.

|

+

|

+

- Once the solution is entered. Recompile and flash Grbl. This

solution model is only

|

+

valid for this particular set of data. If the machine is altered,

you will need to

|

+

perform this experiment again and regenerate a new model here.

|

+

|

+OUTPUT:

|

+

The solver produces a set of values that define the piecewise fit

and can be used by

|

+

Grbl to quickly and efficiently compute spindle PWM output voltage

for a desired RPM.

|

+

|

+

The first two are the RPM_MAX ($30) and RPM_MIN ($31) Grbl

settings. These must be

|

+

programmed into Grbl manually or setup in defaults.h for new

systems. Altering these

|

+

values within Grbl after a piece-wise linear model is installed

will not change alter

|

+

model. It will only alter the range of spindle speed rpm values

Grbl output.

|

+

|

+

For example, if the solver produces an RPM_MAX of 9000 and Grbl is

programmed with

|

+

$30=8000, S9000 may be programmed, but Grbl will only produce the

output voltage to run

|

+

at 8000 rpm. In other words, Grbl will only output voltages the

range between

|

+

max(RPM_MIN,$31) and min(RPM_MAX,$30).

|

+

|

+

The remaining values define the slopes and offsets of the line

segments and the junction

|

+

points between line segments, like so for n_pieces=3:

|

+

|

+

PWM_output = RPM_LINE_A1 * rpm - RPM_LINE_B1 [ RPM_MIN < rpm <

RPM_POINT12 ]

|

+

PWM_output = RPM_LINE_A2 * rpm - RPM_LINE_B2 [ RPM_POINT12 <

rpm < RPM_POINT23 ]

|

+

PWM_output = RPM_LINE_A3 * rpm - RPM_LINE_B3 [ RPM_POINT23 <

rpm < RPM_MAX ]

|

+

|

+

NOTE:

The script solves in terms of PWM but the final equations and

values are expressed

|

+

in terms of rpm in the form 'PWM = a*rpm - b'.

|

+

|

+"""

|

+

|

+from

scipy import optimize

|

+import

numpy as np

|

+

|

+#

----------------------------------------------------------------------------------------

|

+#

Configure spindle PWM line fit solver

|

+

|

+n_pieces

= 4 #

Number of line segments used for data fit. Only 1 to 4 line

segments supported.

|

+

|

+#

Programmed 'S' spindle speed values. Must start with minimum

useful PWM or 'S' programmed

|

+#

value and end with the maximum useful PWM or 'S' programmed value.

Order of the array must

|

+#

be synced with the RPM_measured array below.

|

+#

NOTE: **

DO NOT USE DATA FROM AN EXISTING PIECEWISE LINE FIT. USE DEFAULT

GRBL MODEL ONLY. **

|

+PWM_set

=

np.array([2,18,36,55,73,91,109,127,146,164,182,200,218,237,254],

dtype=float)

|

+

|

+#

Actual RPM measured at the spindle. Must be in the ascending value

and equal in length

|

+#

as the PWM_set array. Must include the min and max measured rpm

output in the first and

|

+#

last array entries, respectively.

|

+RPM_measured

=

np.array([213.,5420,7145,8282,9165,9765,10100,10500,10700,10900,11100,11250,11400,11550,11650],

dtype=float)

|

+

|

+#

Configure line fit points by 'S' programmed rpm or PWM value.

Values must be between

|

+#

PWM_max and PWM_min. Typically, alter these values to space the

points evenly between

|

+#

max and min PWM range. However, they may be tweaked to maximize

accuracy in the places

|

+#

you normally operate for highly nonlinear curves. Plot to visually

assess how well the

|

+#

solution fits the data.

|

+PWM_point1

= 20.0 #

(S) Point between segments 0 and 1. Used when n_pieces >= 2.

|

+PWM_point2

= 80.0 #

(S) Point between segments 1 and 2. Used when n_pieces >= 3.

|

+PWM_point3

= 150.0

# (S) Point between segments 2 and 3. Used

when n_pieces = 4.

|

+

|

+#

----------------------------------------------------------------------------------------

|

+

|

+#

Advanced settings

|

+

|

+#

The optimizer requires an initial guess of the solution. Change

value if solution fails.

|

+slope_i

= 100.0;

# > 0.0

|

+

|

+PWM_max

= max(PWM_set)

# Maximum PWM set in measured range

|

+PWM_min

= min(PWM_set)

# Minimum PWM set in measured range

|

+plot_figure

= True #

Set to False, if matplotlib is not available.

|

+

|

首先設定GRBL 設定 '$30=255' and '$31=1' 再燒錄到arduino uno,啟動Cyclone PCB,恢復設定。 接著看你用什麼轉速計去測量 ,像我是用非接觸式的,需要反光去讀取主軸轉速,所以在主軸貼上不反光的膠帶。

再打開文件 fit_nonlinear_spindle.py

找到:

RPM_measured =np.array([213.,5420,7145,8282,9165,9765,10100,10500,10700,10900,11100,11250,11400,11550,11650],dtype=float)

你再依PWM set 上的陣列第1個數值為2,在bCNC 命令列上數入 M3 S2

可是馬達並沒有轉動,再將數值調高,直到Cyclone 主軸會轉動,這時再去測量主軸轉速。 再將測量的主軸轉數值填入到 RPM_measured 上的陣列第1個數值改為測量到的數量1622,就這樣依序設定,量測,修改,直到全部的數字都對應到量測到的數值。

| bCNC 命令列上數入 M3 S2 |

| 測量主軸轉速 |

最後這台白色cyclone PCB 的測量的數字是:

PWM_set = np.array([10,18,36,55,73,91,109,127,146,164,182,200,218,237,254], dtype=float)

RPM_measured = np.array([1622,3098,6696,9570,10782,11730,12303,12833,13199,13391,13630,13844,14054,14210,14500], dtype=float)

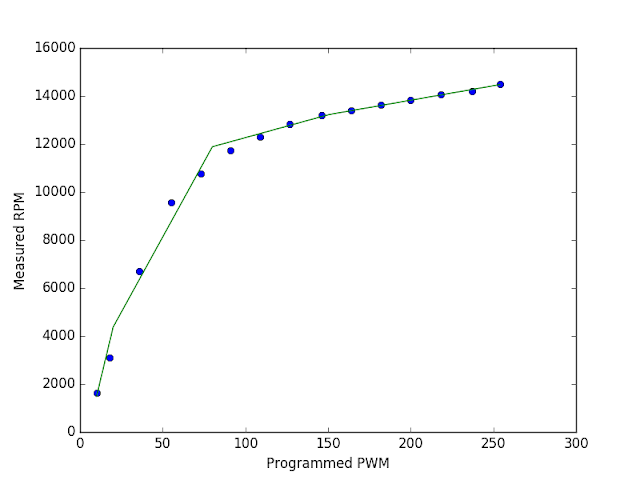

再執行 fit_nonlinear_spindle.py 就會得到一堆數字 ,及一張非線性對應曲線

這時再重新啟動Cyclone PCB,這時你可以命令列中 輸入主軸轉速,實際量測主轉速,是不是接近實際值。

非線性主軸速度PWM輸出,就像是3D列表機的擠出頭溫度控制PID值校正,每個主軸有各自的曲線修正,GRBL 把這個修正函數寫到韌體內,直接用G-CODE 去設定主軸速度,由韌體修正主數轉。

如同前言:Open Source的最大好處就是擁有全世界的工程師協助解決問題並提出創新的技術.那真的是件很棒的事情。

如同前言:Open Source的最大好處就是擁有全世界的工程師協助解決問題並提出創新的技術.那真的是件很棒的事情。

沒有留言:

張貼留言